![]() (065) 6245 0300

(065) 6245 0300

Blk 3016 Bedok North Ave 4 #04-20 Eastech BuildingSingapore 489947

![]() (065) 6245 0300

(065) 6245 0300

Blk 3016 Bedok North Ave 4 #04-20 Eastech BuildingSingapore 489947

HOME > Products > Proportioning Equipment > Balanced Pressure Pump Proportioning Systems (Pump Skids)

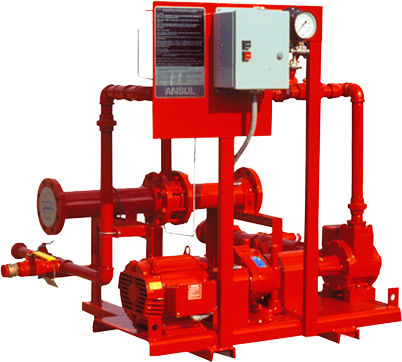

The Balanced Pressure Pump Proportioning System functions by maintaining an equal pressure in the foam concentrate and water inlets to the proportioner, allowing the proportioner to be used over a wide range of flows and pressures. The system connects to an atmospheric storage tank which allows refilling during operation. Controls respond quickly and accurately to changes in the water inlet pressures and flow rates.

The system operates by passing the required portion of foam concentrate from a positive displacement pump to a venturi proportioner with the remaining portion recirculating through a diaphragm valve in the return line to the tank. The diaphragm valve senses and balances the pressure (which can also be balanced manually) in the foam and water lines to the proportioner. The foam concentrate then enters the proportioner where a built-in orifice regulates the flow of pressurized foam concentrate entering the water stream.

These systems are typically used to protect tank farms, marine docks, chemical processing plants, offshore oil platforms, aircraft hangars and loading racks.

The skid units are available in six proportioner sizes ranging from 2 to 8 in. with flow rates from 30 to 5500 gpm (114 to 20,816 Lpm). Each unit consists of a positive displacement foam pump with electric motor and starter; various control, drain, and check valves; pressure balancing diaphragm valve; duplex gauge; foam proportioner; interconnecting brass pipe; and stainless steel valve identification and system instruction nameplates.

Pump Skids are used in combination with atmospheric storage tanks.

Pump Skids

While foam concentrate is pumped from the tank to the proportioner, an automatic pressure balancing valve matches foam concentrate pressure to water pressure.

Instead of using pressurized water as with bladder tanks, the foam liquid is pumped to the proportioner. An automatic pressure balancing valve regulates the foam concentrate pressure to match the water pressure. A duplex pressure gauge provides continuous monitoring of both water and concentrate pressures. The system can also be operated manually to control the pressures and isolate the automatic balancing valve.

Positive displacement pumps are used with these systems to allow maximum efficiency for liquids of varying viscosity. The size of pumps and drivers will vary depending on the application and the type of foam concentrate used.

Atmospheric Poly Foam Storage Tank

An Atmospheric Foam Concentrate Storage Tank is one component of a foam proportioning system. The high density cross-linked polyethylene (XLPE) storage tanks are compatible with all ANSUL foam concentrates, both synthetic and protein.

Because of the properties of XLPE relating to stress crack resistance, impact strength, light weight and overall toughness, poly tanks are an excellent choice for many foam system applications. An atmospheric concentrate tank is typically used in conjunction with a balanced pressure pump proportioning skid unit or in-line balanced pressure proportioning system. Additionally, similar tanks could be used with a line proportioning system.

The atmospheric poly foam concentrate tanks are supplied with fittings. There are two (2) return fittings provided on all tanks located 180 degrees apart to enable ease and flexibility for piping on site. Either connection can be used as the foam concentrate return with the other return connection having the provided pipe plug installed. The poly tanks are translucent and have a level gauge strip for approximating tank contents.

Download brochure here: View